Environmental chamber for spinning disk microsope.

All loose parts, such as syringe for injecting water into the system, should be stored in the clear plast box labeled Tokia Hit Parts.

For a short version of the instructions see p. 34 of the manual. However, we recommend reading the entire manual.

When reading the manual, look at the instructions for STXG version of the incubation system.

Official manual, PDF format

The manual recommends setting up the environmental chamber an hour before use. Therefore, set it up before bringing samples to the room.

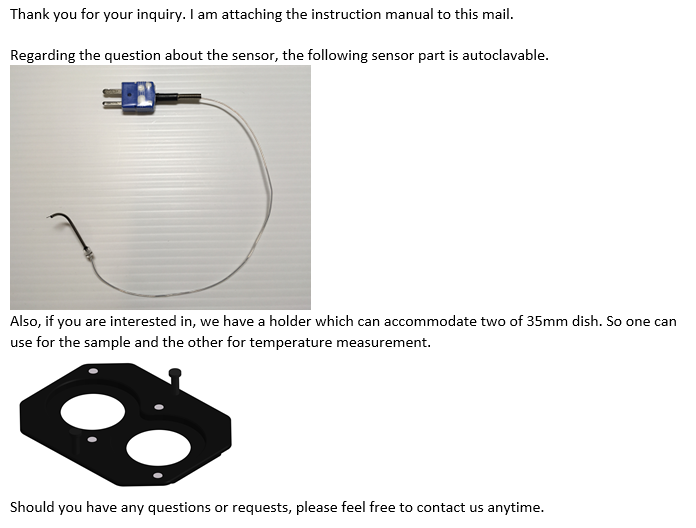

For the temperature unit to work properly, it needs feedback from a sensor. This sensor may be in the dish of cells (please see manual page 25).

They sell a special stage insert that fits two dishes so that one may be used for imaging andthe other may have the temperature sensor in it.

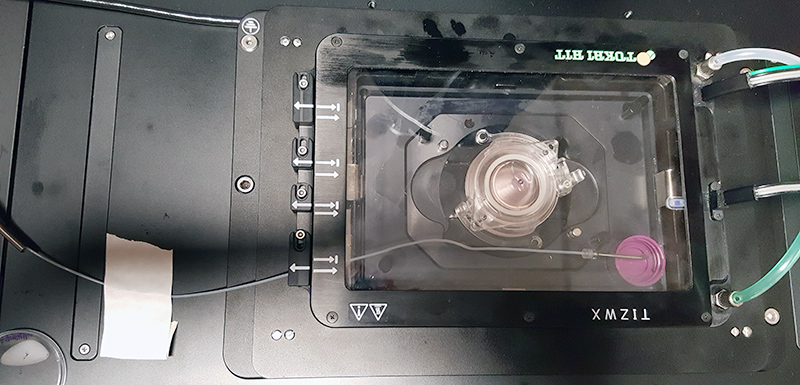

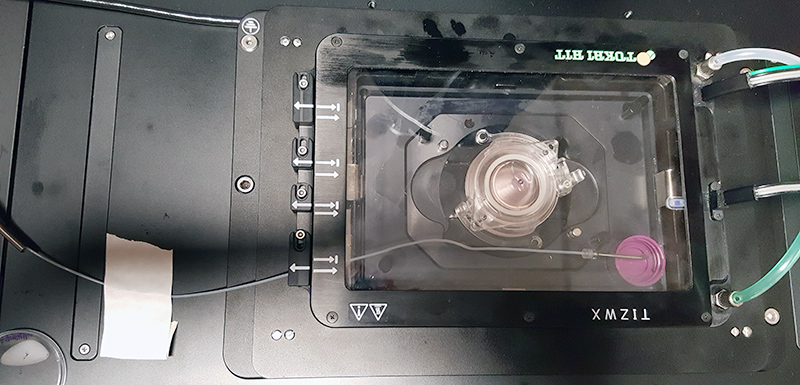

We do not own this plate insert, but have what we think may be an alternative solution using the cap from a conical tube filled with water. Note the tape holding the wire in place on the stage.

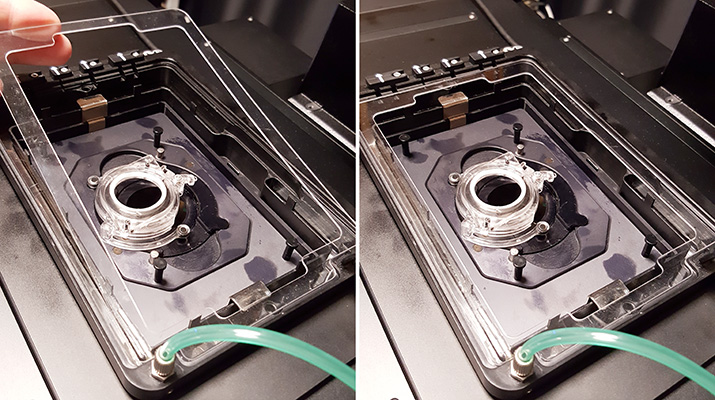

The chamber should be hydrated. The manual suggests 26 ml of distilled water in the metal trough at the perimeter of the stage insert.

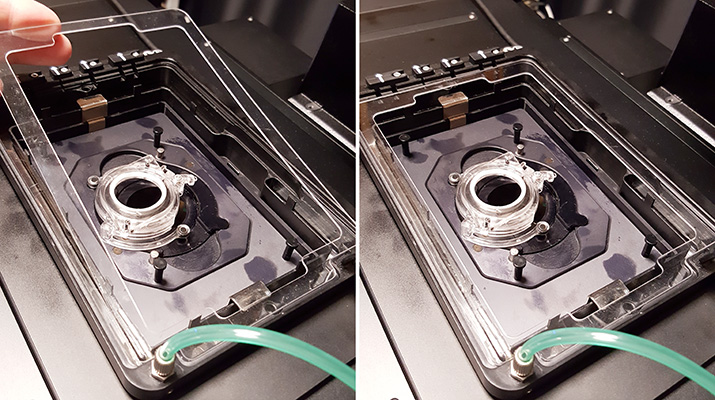

Pictures show water being added to the system and the clear plastic lid being installed after water added.

At the end of the session, please suck out water and dispose of somewhere (sink, garbage can...).

Moving live samples to the scope room.

Hours before moving samples to the scope room, put freezer packs for shipping or metal block in water bath or incubator to make it the same temperature as the samples.

Put your sample on top of this for the trip to the microscope room.

If using CO2

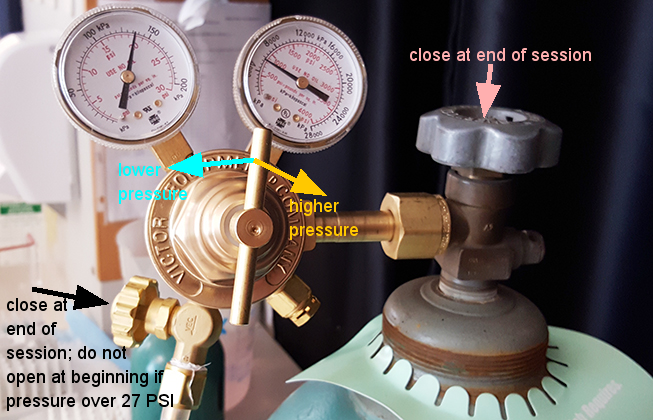

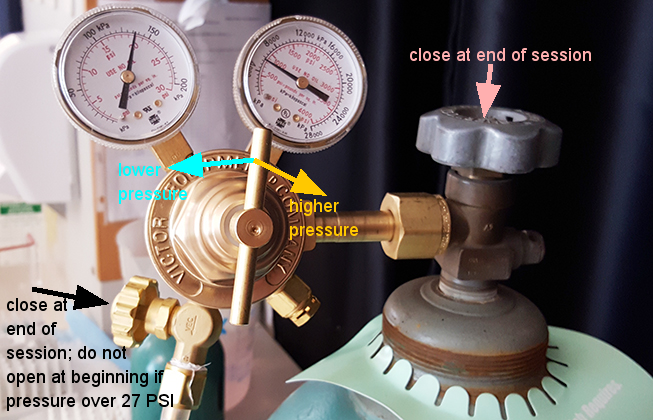

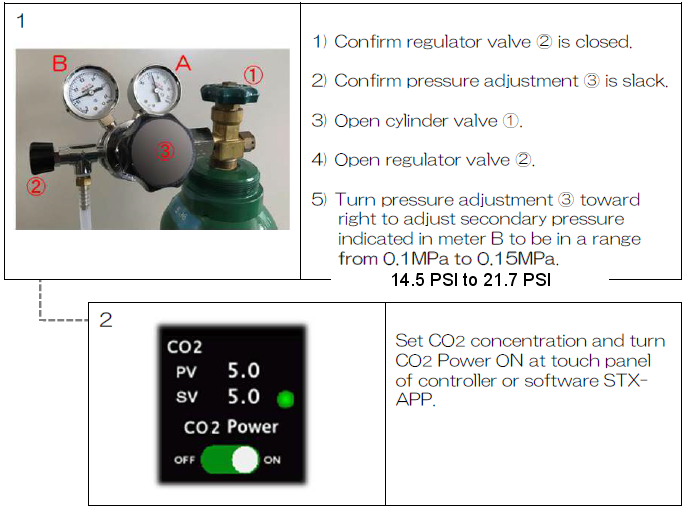

Before opening the main valve on the tank, make sure that the valve at the hose is closed. This is important to prevent high pressure from going to the Tokai Hit unit which could damage it.

With the hose valve closed, open the main tank valve and adjust the pressure to be less than 27 PSI.

After opening the valve, the pressure can be set between 15 and 27 PSI for operation. As pictured, the pressure is at 20 PSI.

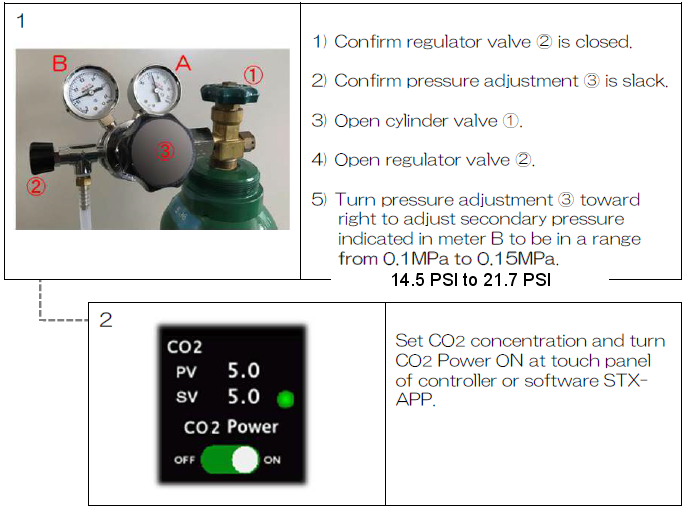

From p. 35 of the manual:

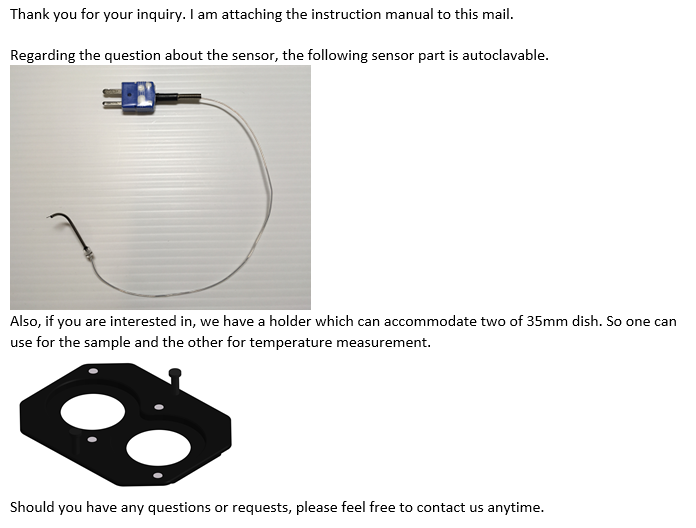

Something we probably won't do, so please wash the sensor with 70% ethanol.

Email from tech support about snsor:

<back